What is the challenge

Replacing batteries has become a major pain for industries that deploy a big amount of sensors and need reliable uninterrupted data. Some batteries run out of power earlier than others, some of them are difficult to reach. This can lead to loss of important data requiring constant monitoring that comes at a cost.

Battery failures, battery replacement and limited battery lifetime all beg the same question – Why do we need them? The significant time and cost to replace batteries is obvious, but what about the hidden problem – the impact on data gathering? How can analysis be complete when there are monitoring gaps? How can analysis be comprehensive when collection intervals are designed to suit a battery and not your needs?

Fortunately, the new breakthrough solutions like the one you are going to read about, can solve these problems once and for all.

The solution that makes sensors auto-charge wirelessly

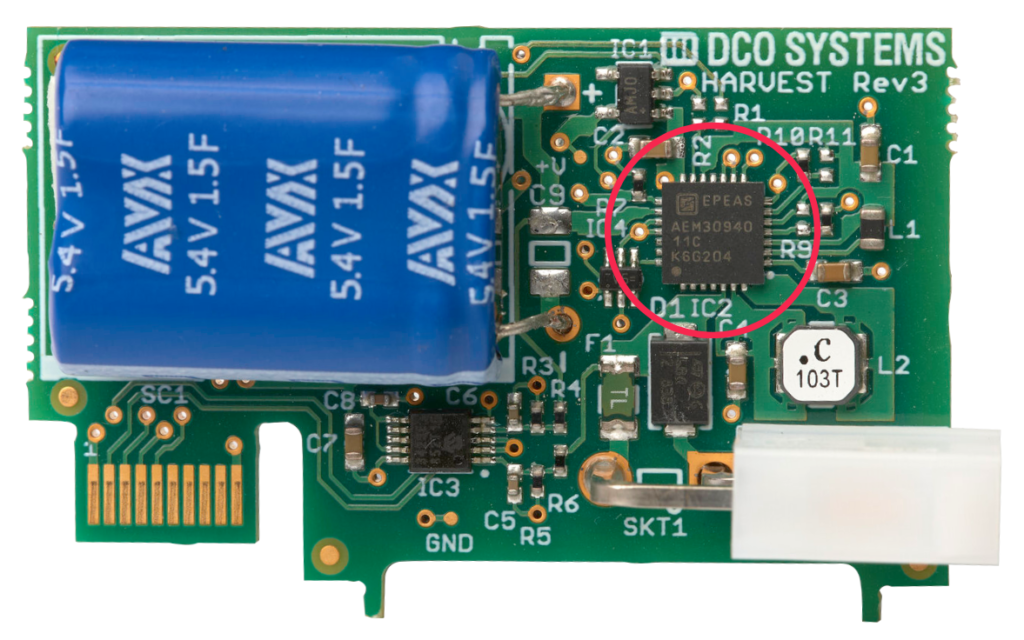

DCO Systems have developed an energy harvesting solution for equipment monitoring sensors driven by e-peas’ Ambient Energy Managers that allows sensors to auto-recharge either from heat, light, vibration, and ambient electromagnetism. This kind of energy can be found everywhere, even in remote and inaccessible locations that have limited access and minimal infrastructure.

Once this solution is integrated into your sensor, there will be no need to change the battery anymore, it becomes maintenance-free. You can opt for a rechargeable battery or remove it completely by substituting it with a supercapacitor storage element. E-peas’ energy harvesting technologies will harvest energy and store it for when it is needed.

Where can it be used?

As manufacturing industries implement the Industrial IoT, energy harvesting sensors are becoming a rising star. DCO Systems are using this technology to enhance machine monitoring techniques for equipment including heat exchangers, actuators, motors, air handlers, heat recovery units, steam traps, boilers and pipework.

Measurable elements provide insight into equipment performance, process efficiency, steam generation and distribution, predictive and preventative maintenance needs, and fault diagnostics and alerts. Furthermore, energy harvesting sensors are ideal for engineers overseeing multiple plants or off-site locations with little infrastructure or access.

Examples of existing sensors

4 immediate benefits of using energy harvesting sensors:

- Complete information – no gaps in monitoring. Energy harvesting creates the conditions for more frequent data reporting and always-on, real-time connection of your equipment and assets. More than that, our sensors adapt, measuring their harvesting and dynamically adjusting power use to suit operational and reporting constraints you set.

- Simplification and ease of use – Energy harvesting sensors have a simple plug and play installation. This means, any employee can install the self-powered sensor to a machine, and it is ready to harness data immediately.

- Battery-free and maintenance-free – Battery-free, energy harvesting sensors do not need routine maintenance, they work non-stop without battery changes. Furthermore, this makes self-powered sensors an ideal choice for remote monitoring in hard to access locations and sites with limited existing infrastructure.

- Zero-waste – Energy harvesting sensors are vital for reducing a plants overall energy usage and reaching zero-waste. The simplicity of harvesting energy from the surrounding environment, something that is already there, and using it generates zero waste.

“DCO Systems are building sensing solutions that are affordable, accessible and maintenance-free. The inclusion of e-peas’ energy harvesters means that our sensors can be more active, are more easily installed and avoid battery dependency. Harvested power allows more frequent and comprehensive reporting, delivering a richer data set for engineers and site operators,” explains Andrew Doherty, DCO Systems founder and Managing Director.

Technical specifications

DCO offers two types of sensors available for machine and equipment monitoring:

- Compact version rated for internal use has an overall size of 110 x 56 x 41mm

- IP68 rated version for outside / hostile environment use has an overall size of 130 x 90 x 63mm

Both sensors collect information on:

- Power (electrical power, consumption data & power analysis)

- Temperature and humidity (contact & non-contact)

- Pressure (air, gas, steam & water)

- Sound and vibration (motors, gearboxes & mechanical assemblies)

- Vision (infrared and visible light)

- Level, volume and flow

The inclusion of the e-peas energy harvesting component means that these measurable elements are continuously monitored, non-stop. There are two e-peas’ ambient managers used in DCO solution depending on type of energy available in your environment:

AEM20940 – TEG Harvesting solution, Low Grade DC Source Solution

- Vin 50 mV to 5 V

- Cold start 60 mV @ 150 μW

- Pin 3 μW to 550 mW

- Pout 20 mA @ 1.2-1.8 V and 80 mA @ 1.8-2.5-3.3 V

- MPPT Yes

- Package QFN28 / 5 x 5 mm

AEM30940 – AC Current Harvesting Solution

- Vin 50 mV to 5 V

- Cold start 3 μW @ 380 mV

- Pin 3 μW to 550 mW

- Pout 20 mA @ 1.2/1.8 V and 80 mA @ 1.8-4.1 V

- MPPT Yes

- Package QFN28 / 5 x 5 mm

How to purchase the sensor?

Sensors for specific applications are already available with extensive customisation possible through sensing, communications, and energy harvesting options. Equally important is that the customer can easily install all sensors. Furthermore, DCO has evaluated installers’ practical needs and included coordinated connectors, adapters, and fittings for many different requirements, with installation videos that lend additional support if needed. The ease of installation and use means that these energy harvesting sensors can be up and running immediately. For a personalised quote or to order DCO Systems’ energy harvesting sensors, please visit their website at dcosystems.co.uk or call +44 (0)1285 359050.

About e-peas

e-peas develops and markets disruptive ultra-low power semiconductor technology. This enables industrial and IoT wireless product designers to substantially extend battery lifespans and eliminate the heavy call-out costs of replacing batteries, without in any way compromising on reliability. Relying on 15 years of research and patented intellectual property, the company’s products increase the amount of harvested energy and drastically reduce the energy consumption of all power consuming blocks within wireless sensor nodes. Headquartered in Mont-Saint-Guibert, Belgium, with additional offices in Switzerland and the USA, e-peas offers a portfolio of energy harvesting power management interface ICs, microcontrollers and sensor solutions.

Website: www.e-peas.com

LinkedIn: linkedin.com/company/e-peas

Twitter: https://twitter.com/epeas_news

YouTube: https://www.youtube.com/c/epeas

About DCO Systems

DCO Systems provide affordable, energy harvesting equipment sensors and software that enable industry to implement, upgrade and extend existing monitoring efforts. Pioneering a synergy of mechanical engineering and IT knowledge, DCO improves monitoring techniques widely utilised today but makes them automatic, persistent and simpler. DCO’s solutions can be integrated with existing monitoring systems and are easily installed or retrofitted to equipment. Located in Cirencester, England, DCO’s sensing solutions benefit a wide range of industries from healthcare to tea processing.

Website: https://dcosystems.co.uk/

LinkedIn: https://www.linkedin.com/company/dco-systems/

Twitter: https://twitter.com/DCOSystems

Dual source harvesting

Dual source harvesting